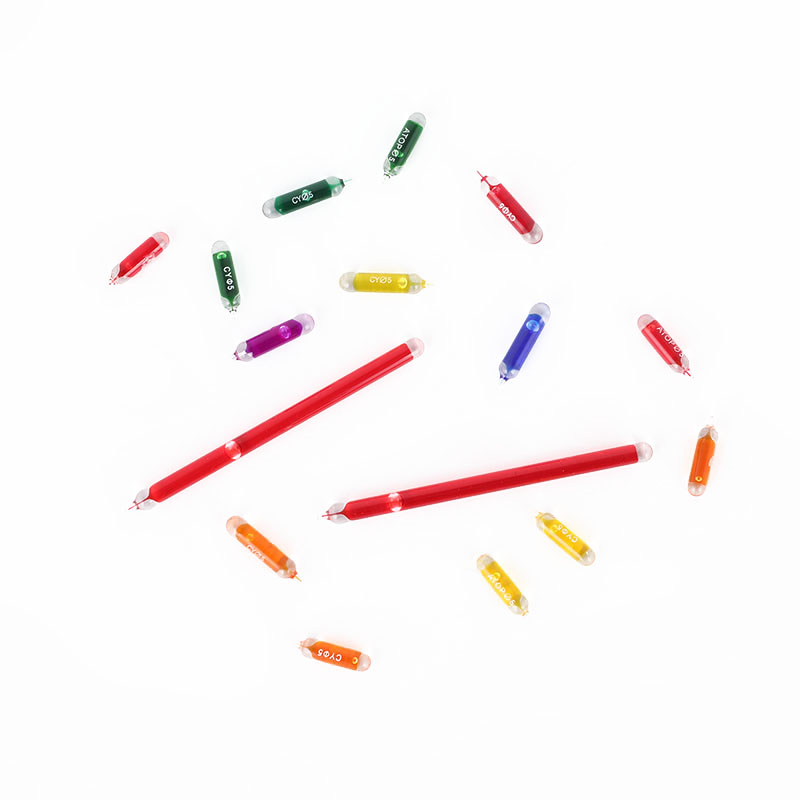

Standard response sprinkler bulbs (short type)

| Size(mm) | Temperature Rating(℃/°F) | Color | |

| A | 3.8 | 57℃ / 135°F | orange |

| B | 2.02 | 68℃ / 155°F | red |

| C | <4.5 | 79℃ / 175°F | yellow |

| D | 5±0.1 | 93℃ / 200°F | green |

| d1 | 5.1±0.2 | 141℃ / 286°F | blue |

| d2 | 5.1±0.3 | ||

| L | 19.8±0.5 | ||

| l1 | 16±0.4 | ||

| l2 | 15.8±0.4 | ||

| Glass bulb load(N) | Average Cursh load(X) | 4000 | |

| lower Tolerance Limit(TL) | ≥2000 | ||

| Maximum clamping torque | 3.5 N·cm | ||

| Response time index(m*s)0.5 | 80<RTI≤350 | ||

Although it is smaller, each product is subject to strict factory inspection before leaving the factory, including appearance, size, static action temperature and crushing load test.

During the static action temperature test, the test ambient temperature is (20 ± 5) ℃, and the test is carried out in liquid bath. Water bath (distilled water is preferred) shall be adopted for glass bulbs with nominal operating temperature not higher than 79 ℃, and oil bath (oil products suitable for nominal operating temperature) shall be adopted for glass bulbs with nominal operating temperature higher than 79 ℃. The temperature of the test liquid bath shall be uniform, the temperature deviation in the test area shall not exceed 0.5 ℃, and the temperature measurement accuracy shall not be less than ± 0.1 ℃.

Place the glass bulb sample vertically in the liquid bath. The distance between the center of the glass bulb and the liquid level is not less than (40 ± 5) mm. Raise the temperature from room temperature to (20 ± 2) ℃ lower than the nominal operating temperature at a heating rate of not more than 20 ℃ / min. after holding for 10 minutes, raise the temperature at a rate of 0.4 ℃ / min ~ 0.6 ℃ / min until all the samples are broken. Record the operating temperature of each sample, Judge whether the test results exceed the following temperature range:

X ±(0.035X + 0.62)

X -- Nominal operating temperature, unit: Celsius (℃).

My company's main fire products are: sprinkler head, spray head, water curtain sprinkler head, foam sprinkler head, early suppression quick response sprinkler head, quick response sprinkler head, glass ball sprinkler head, hidden sprinkler head, fusible alloy sprinkler head, and so on.

Support ODM/OEM customization, according to customer requirements.

1.Free sample

2.Keep you updated with our production schedule to ensure you know each process

3.Shipment sample for checking before shipping

4.Have a perfect after-sales service system

5.Long term cooperation, price can be discounted

1.Are you a manufacturer or trader?

We are professional manufacturer and trader for more than 10 years, you are welcomed to visit us.

2.How can I get your catalog?

You can contact via e-mail, we’ll share our catalog with you.

3.How can I get the price?

Contact us and tell us your detail requirements, we’ll provide accurate price accordingly.

4.How can I get sample?

If you take our design, the sample is free and you pay shipping cost. If custom your design sample, you need to pay sampling cost.

5.Can I have different designs?

Yes, you can have different designs, you can choose from our design, or send us your designs for custom.

6.Can you custom packing?

Yes.

The products will pass strict inspection and screening before leaving the factory to eliminate the output of defective products

We have many imported processing equipment to support the manufacturing of various fire sprinklers, hardware and plastics.